|

|

Design, Inventions and Engineered Projects This is a collection of projects that are otherwise not classified in my online portfolio. I have broken them down into personal and commissioned work. |

|

|

|

Personal Projects

I have an arms length list of potential projects for myself, many of which I will never get to start let alone finish. I do however manage to get to a few of them. Here is a quick summary of some of the project I have accomplished outside of working. My fighting robot endeavours would be in this list, but they were such a large part of what I did from 1998-2003 that they get their own page. |

|

All Classic Japanese Car & Bike Show Trophies In 2005, I sponsored the All Classic Japanese Car & Bike Show held by the Datsun 510 Club of BC by designing and building the prize trophies out of CNC machined acrylic and aluminum. |

Acrylic "wheel" portion of award 1600 x 1200 |

Assembled trophies |

My 510 at the show to the left of an all original 510. 1600 x 1200 |

|

Connecting Rod Key Fob Bottle Openers To raise funds to compete in Targa Newfoundland 2004 I produced a run of 80 of these CNC machined aluminum bottle openers. Roughly modeled after my Datsun 510's L18 connecting rod, these were sold online to fellow members of Something Awful's car forum "Automotive Insanity". |

Prototype opener with keys 1600 x 1200 |

Backside, penny for scale |

It opens bottles! |

Production run 1600 x 1200 |

|

Caterham Super 7 Side Mirror Mounts Prior to competing at Targa Newfoundland 2004, I built these adjustable mirror mounts for my father's Caterham Super 7. He mailed me the mirror and along with photos and dimensions of the mounting locations, and I designed and machined the parts. They were put on the car once I reached Newfoundland for the event. |

Mirror and mount |

Post rally Super 7 with mirrors installed 1600 x 1200 |

|

Custom Urban Cruiser For my girlfriend's birthday in 2004, I decided to build her a custom bike. This project was a lot of fun and has a page dedicated to it. |

Used Norco cruiser frame |

Machined drop out |

Disc brake adaptors on Skyway wheels |

Finished bike |

|

Nissan NX2000 Hatch Cover Pins Intended initially for my own use, I designed and machined billet aluminum pins to replace the broken plastic ones in my car. Knowing that other NX owners faced the same inadequate OEM solution, I did a production run of 30 pairs of these and sold them online. See this page for purchasing information. |

My 1992 NX2000 1600 x 1200 |

Prototype pins |

Prototype pin in place |

Production set with hardware 1600 x 1200 |

|

Ultra-Laminates Prototype In the fall of 2003 I completed what would become the prototype to my Ultra-Laminated Baltic Birch furniture line. Designed to be my everyday coffee table, it could be extended to be as large as needed or retracted and tucked away. The design lent itself to efficient production through nesting. I showed the piece at the 2003 Eastside Culture Crawl and the positive feedback led me to developing my current line of furniture. The prototype table is made of pine plywood, has a high gloss finish, and machined Ultem 1000 feet. |

Raw plywood shapes 1600 x 1200 |

Midway through finishing 1600 x 1200 |

Extended table 1600 x 1200 |

Retracted table 1600 x 1200 |

|

Lighting Experiments During 2003 I produced my first lamps. The 8-element lamp was based on a bathroom wall fixture with scrap-yard aluminum tubing (oxidation and all) surrounding high efficiency florescent bulbs. These bulbs were shaded with pages torn from an unopened $95, 225-page engineering textbook titled "Designing Linear Control Systems with MATLAB", duct taped to the aluminum. Very raw and unfinished, it was a change of pace for me. I also built a series of four highly finished high-density polyethylene lamps, which used clear and yellow plastic to warm up the tones of high efficiency florescent bulbs. I sold one, gave two away and kept one. I would like to experiment more in the future with lighting, specifically using florescent bulbs and emerging LED technology. |

8-element lamp 1600 x 1200 |

Detail of shades 1600 x 1200 |

HDPE lamps 1600 x 1200 |

1600 x 1200 |

|

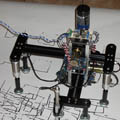

Mobile Plotter In the fall of 2002 I spent some after work hours at Pathway Design CNC machining the parts to scratch-build this mobile plotter robot. The idea was to design a robot that could write in chalk on pavement, with the ability to create large works. Using a simple alphabet based on a 5x5 point grid and a Microchip PIC16F873 based controller, the robot ran during the 2002 Eastside Culture Crawl using Sharpie markers. It created a large "HELLO WORLD" test pattern and a couple of smaller pieces. The weekend took its toll on the machine and an electrical component and motor failed ended its plotting career. The robot has been inactive since then, but has been rented on occasion to local TV/film productions to be used as set dressing. |

SolidWorks model of plotter in action |

Test assembly prior to anodizing 1600 x 1200 |

Assembled robot 1600 x 1200 511KB .WMV of working plotter |

Resultant test pattern 1600 x 1200 |

|

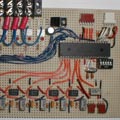

Undergrad Thesis: Semi-Automatic Transmission A project that started in 2000 and ended with the completion of my Engineering degree in 2001, I designed and built a pneumatic F1-style semi-automatic transmission for my Datsun 510 wagon. This project has page dedicated to it. |

The car: 1972 Datsun 510 Wagon |

Actuators in place on transmission |

Wheel with shift paddles |

Microchip PIC controller |

|

|

|

Commissioned Projects These are projects I have completed for clients and employers outside of film and television work. LightShed by Liz Magor I did a small amount of Work on Liz Magor's amazing LightShed (2004) -- creating the digital 3D representation of the corrugated roof texture. After the installation of the piece I CNC machined the information plaque that accompanies the sculpture, which it seems everyone reads. Look for it the next time you're on the Coal Harbour seawall. |

LightShed |

Plaque |

|

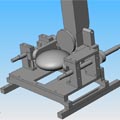

Jade Bead Carving Machine In the fall of 2004 I designed, programmed, machined and assembled this specialized fixture. It was designed to swing an angle grinder through a very specific quarter ellipse. The machine was used in conjunction with a potter's wheel to carve jade beads for a large Abacus, destined to become public art in Vancouver. |

SolidWorks model |

Finished mechanism 1600 x 1200 |

Dual lead screws driven by a linked chain drive 1600 x 1200 |

1600 x 1200 |

|

Patio Waterfall Summer 2004 saw me engineering an outdoor water feature for a wealthy Vancouver client. I broke down his design into a build able structure. It was made of structural aluminum extrusions and CNC water-jet cut anodized aluminum panels. It needed to be assembled on site, as it reached the client's 30th floor apartment by elevator. Assembly was straightforward and a glorious artificial waterfall was created. |

Base grid work with leveling feet |

About half way done assembly -- it required no on site welding |

Finished fountain minus the client's rocks and sculptures 1600 x 1200 |

Detail of water 1600 x 1200 |

|

Adjustable X-Ray Stage In 1999 while working as a co-op at Tantus Electronics I designed this adjustable stage for their experimental X-ray enclosure. This was my first project ever with SolidWorks, and my first real professional mechanical design experience. The assembly was farmed out to a machine shop to build. |

At its highest setting |

Slots hung on pressed in roll-pins |

Second lowest setting |

Under carriage bracket for ultra low setting |

|

|

|

Derek Young Home - Design, Inventions and Engineered Projects |

|

|

© Derek Young 1997-2005 |